PIX TRANSMISSONS LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PIX TRANSMISSONS LTD.

Wrap Construction Belts

Specification

- Special CR treated outer jacketing fabric for higher durability

- Anti-static, oil & heat resistant

- Maximum Belt linear speed (Classical section: Up to 30 m/Sec, Wedge section: up to 42 m/Sec, Narrow section: up to 45 m/Sec)

- Temperature range: -18°C to +80°C

- ATEX certified FRAS Belts are also available

Anti Static Or Wrap Belts

Features

- Ensures high level of protection against fire hazards

- Fire resistance properties complies as per IS 2494 Part-II standard

- Anti-static values found 10 to 15 times superior than the maximum specific value, as per ISO 1813

- All FRAS Belts are ATEX certified

- Resistance to emit inflammable substances, while in operation

- Damage-free and crack resistance

- Longer service life

- Anti-static, oil and heat resistant

- Extended temperature range: -25˚C to +100˚C

Variable Speed Wrap Belts

Features

- Excellent transverse rigidity and flexibility to prevent bucking at minimum diameter settings, where Belt stress is more

- Firm gripping action with the contact area; provides positive traction for precise speed control

- Higher power transmission capacity

- Longer service life

- Facilitates smooth running without excessive vibrations

- Specific Belt design for maximum longitudinal flexibility

- Temperature range: -18°C to +80°C

Narrow Section Belts

Features

- Oil resistant & antistatic

- Maximum Belt linear speed (Classical section: up to 30 m/sec, Wedge: up to 42 m/sec, Narrow: up to 45 m/sec)

- Superior transverse stiffness & high wear resistance

- Suitable for drives with small pulley diameters, high ambient temperature & speed

- Temperature range: -25ºC to +100ºC

- ATEX certified FRAS Belts are also available

Banded Belts

Features

- Enhanced power transmission capacity up to 25%

- Lesser number of Belts required as compared to multiple single-Belt drive

- High adhesion strength between tie band and the Belts

- Eliminates chance of mismatch in length as observed in multiple single-Belt drive

- Antistatic, oil and heat resistant

- ATEX certified FRAS Belts are also available

- Temperature range: -25ºC to +100ºC

- Manufactured through a single-stage-curing process

Fire Resistant Antistatic Belts

Features

- Conforms to: II 2GD c IIB X (Test report no. IB-03-4-934) - ATEX

- Temperature range: -25˚C to +100˚C

- Ensures high level of protection against fire hazards

- Fire resistance test shows that the flame &the glow time period is less than the desired 5 seconds, maximum time as per IS 2494 Part-II standard

- Antistatic values found 10 to 15 times lower than the maximum specified value, as per ISO 1813

- All FRAS Belts are certified by ATEX

- Resistance to emit inflammable substances while in operation

- Damage free and crack resistance properties to ensure smooth operation

- Longer service life

- Dimensional stability

- Antistatic, oil and heat resistant

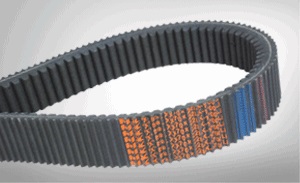

Double Cog Variable Speed Belts

Features

- Reduced bending stress allows the Belt to transmit maximum power on smaller pulley diameters

- Cog profile on both the sides provide excellent flexibility, facilitating longer service life

- Excellent drive performance even at elevated temperatures, the spacing between the cogs facilitates better heat dissipation

- Tension member placed at the neutral axis of this Belt provides low stretch properties

- Smooth functioning as a result of transverse rigidity, greater toughness & superior finish

- Robust construction helps superior power transmission capacity

- Wear resistant sidewalls to provides the best wedging effect and higher efficiency

- Equipped to withstand flexing action, resistant to fatigue and reduce slippage, facilitates smooth performance at extremely high varying loads and rpm

- Superior resistance to oil, heat and are also antistatic

- Temperature range: -25˚C to +100˚C

Textile Machinery Belts

Features

- Designed to meet power transmission requirements in textile spinning mills

- Specially developed for spinning mills to operate at a very high speed

- High power transmission capacity

- Excellent tensile strength

- Excellent performance & customer satisfaction by offering energy saving solutions

- Temperature range: -25˚C to +100˚C

Ribbed Poly V Belts

Ribbed Belts are an ideal solution for compact drives in household appliances and heavy machinery. Ribbed Belts enable economic solutions even under difficult drive conditions, such as large transmission ratios, high Belt speeds, small pulley diameters and back idler pulleys.

Ribbed Belts consist of multiple V-grooves. The design allows operation on small pulley diameters. Ribbed Belts offer high Belt speed. Ribbed Belts are designed for high power transmission ratios and offer high power output.

Ribbed Belts are available in PJ, PK, PL and PM profiles

Double Sided Poly V Belts

Features

- Highly flexible & reduced bending stress

- Suitable for smaller pulley diameters

- Optimum performance even at higher speed

- Suitable for the drives with pulleys rotating in clockwise and anti-clockwise directions

- Twin contact surface area, power transmission through both the sides of the Belt

- Temperature range: -25°C to +100°C

Packaging Machinery Poly V Belts

Features

- Construction comprises of a profile-top-rubber (application-specific)

- Facilitates excellent cushioning coupled with extra elasticity, to the contact material

- Excellent flexibility to prevent cracks or tearing

- Optimum friction, suitable for providing proper support to the contact material

- Vulcanized as a single piece to ensure excellent adhesion

- Abrasion resistant

- Longer service life

- Temperature range: -25°C to +70°C

Timing Belts

Timing Belts are one of the most important part of Power Transmission drives. Timing Belt can be best described as best be described as that Belt with integrally moulded teeth on its inside which makes positive engagement with axially grooved pulley. Timing Belt is also known as synchronous Belt or positive-drive Belt. Timing Belt drive is not considered as a substitute or replacement to other modes of Belt drives.

Timing Belts exhibit important properties such as fixed speed ratio, no re-tensioning after installation, low maintenance with wide variety of power transmission capacities and drive speeds.

Timing belts use teeth that mesh with grooves in a pulley to synchronously drive the system. There is no slippage, which will cause speed variations, allowing drives to be timed very accurately. The tensile cord has minimal stretch so the constant need for take up adjustment is removed.

Timing drives will work over a very wide range of speed and torques. Torque ranges of between very light office equipment to heavy duty crushing equipment up to several hundred kW are also capable of being driven by timing drives.

Its unique feature enables it to use in positive drive resulting in precise movement of drive components.

Packaging Machinery Belts

eatures

Profile top rubber provides excellent cushioning coupled with extra elasticity.

Wide working temperature range from -18˚ to +80˚C.

Provides optimum friction suitable for proper support to contact material

Abrasion resistant

Excellent service life

Belts are designed with abrasion resistance properties

Longer life

Step-cut Belts are also available for smaller pulley diameters, providing extra flexibility

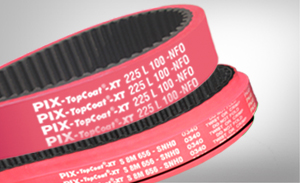

Paint Shop Belts

Features

- Excellent performance while operating at high temperatures

- Higher power transmission capacity compared to standard Timing Belts

- Longer service life

- Ozone, oil, heat and chemical resistance

- Highly flexible and excllent dimensional stability.

- Temperature range: -30°C to +150°C

- Reference standard: ISO 13050

Polyurethane Belts

Features

- Polyurethane timing Belts are highly flexible with longitudinal toughness to ensure perfect tooth meshing

- No dust-generation or flaking while running - clean Belt

- Homogeneous throughout its cross-section by virtue of thermoset moulding process

- Superior wear and abrasion resistance

- High resistance to oil, fat and grease

- Excellent resistance to ageing, hydrolysis, UV and ozone

- Low vibration and reduced noise level

- Good resistance to most acids and alkalis.

Air Cooled Heat Exchanger Timing Belts

Features

- High Tensile Strength

- Higher power transmission capacity in comparison to regular belts.

- Negligible elongation to meet vertical drive requirements.

- Extreme level of dimensional stability.

- Extreme abrasion resistance.

- Free from maintenance & lubrication.

- Longer belt & Pulley life

High Power Timing Belts

Features

- 50% to 70% enhancement in power-rating over PIX-X'act® HTD/STD Belts

- Higher angular speed, resistance to loads and Low noise

- Increased operational efficiency up to 98%

- Optimum operational efficiency and augmented Belt life

- Lower operational cost.

- Antistatic properties as required by ISO 9563

- Standard: ISO 13050

Hybrid Belts For Flour And Rice Mills

Features

- Combines the advantages of Synchronous and Poly V-Belts

- Transverse teeth for positive engagement on one side and longitudinal ribs for non-synchronous frictional transmission on the other side.

- Suitable for multi-shaft transmission with reversed rotary directions of pulleys

- Antistatic, oil and heat resistant

- Noise-free transmission

- Operating temperature range -25ºC to +100ºC

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.